If youre into electric car conversions or off grid power, you will come across large contactors / relays. The thing about them is they are great for having a mechanical disconnect from your battery to prevent draining or to changeover but they consume a lot of power when ON and liberate heat as a result.

Basic way

There are simple ways of creating a power saver circuit. The first is the DC polarised capacitor + resistor combination as shown below.

Basically it works as follows. The Voltage from Bat1 fills up Cb (blocking capacitor), thus energising the relay. Once the capacitor fills up, it’s impedance will rise to the point where the resistor comes into play. The value of the resistor is calculated as a dropping resistor value to keep the coil in a holding state. When Bat1 voltage is turned off, the coil will drain at the rate specified by the Rd,Cb network; t=1/RC.

This works OK except that you can see the holding voltage is directly proportional to the holding current via Ohms Principle (V=RI). This is fine for most applications. However if you want a certain holding voltage (as specified by the manufacturer’s datasheet) and want as low as possible holding current, you will need a better solution. To add, you need to ensure that the holding voltage is sufficient to withstand vibration (if your application calls for it).

Smart way

So you’re thinking in this day and age of microprocessors why not use a GPIO to PWM the relay/contactor coil via a mosfet to achieve current control while keeping voltage at a level you desire?

Well yes why not. Here are 3 ways.

(a) Easy to implement using a spare GPIO but no power saving

(b) You get Power saving through PWM but its fixed and requires tuning. Sometimes you don’t have PWM spare

(c) Use an interfacing IC that is driven by a GPIO HIGH LOW and let that IC do the work of managing power saving.

Uber-smart way (c)

Enter an IC from Texas Instruments called the DRV110. This particular IC is specifically designed to address the power consumption issues with energised coils in relays and contactors.

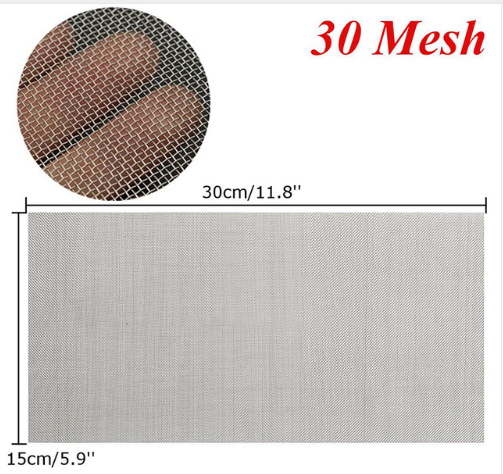

The implementation of the chip is simple and as follows.

As you can see it powers itself from the relay/contactor source. It can sense the current flowing through the coil to allow it to self manage the holding current.

The Peak, Hold and Keep (disengage delay) values can be set via resistors.

Voila! You have a separate holding voltage and holding current capability fully managed by this tiny IC.

Specifications of the IC.

You can see that the Vin value can be setup directly from the MCU or scavenged off the relay/contactor supply via a dropping resistor.

The Ven, turn on voltage works to 7V. So a 1.8V, 3.3V, 5V MCU GPIO can be used to turn it on and off.

The reason I really like this IC is the mosfet is external and up to you. So you can pick a nice low RdsON mosfet to keep the power / heat losses low.

If you wish to buy this IC for your project, please use the link below as it helps me out without extra cost to you.

Texas Instruments DRV110PWR: http://ali.pub/20ovfr

Datasheet for DRV110: http://www.ti.com/product/DRV110/datasheet