I have been a maker pretty much all my life. PCB fabrication has always interested me from constructing prototypes on vero board to toner transfers onto dual sided FR4 board.

As time went on, the through hole components gave way to the SMT parts that initially were OK to install by hand (eg 1206 and to some extent 0603).

My progression to 0402 parts and jittery flair for coffee in the morning has made it quite laborious to work with so I decided just like many makers out there to invest in a PCB assembly line.

Note, in this day and age with the likes of JLCPcb (AKA Shenzen JLC Electronics Co Ltd AKA JiaLiChuang (HongKong) Co Ltd), PCB fabrication at home is now relegated to “doing art” and no longer a practical nor time economical activity. So we will just focus on assembling fabricated PCBs using a commercially made Stencil.

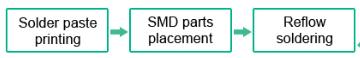

The Process

Well this one is real simple. We will take a commercial assembly process and reduce it down we get the following process.

We will need a Solder Paste Printer, a pick and place machine and a reflow oven.

Solder Paste Printer

After much research and my own experiences setting up stencil jigs, I want a printer that allows fine scale control over the levelness of the pcb while “squeegeeing”.

Enter the 3040 Printer.

Features:

- Work table size: 300*400mm (Pretty much standard low cost stencil from JLCPcb)

- Print size: 250*400mm

- Max net frame size: 370*470mm

- Thickness of the substrates: 0-80mm

- Workbench adjustment volume: 10mm Horizontal Angle adjustment

- Printing platform height: 220mm

- Claimed Repeated accuracy: +-0.01mm

- Locate mode: Benchmark or hole shape Dimension 540*370*350 mm

- Weight: 25Kg

Pick & Place Machine

I want something that has some good reviews already and the thumbs up from fellow makers. I don’t need something with a million feeders but I do want something with around 20-30 feeders, a separate IC tray area and possibly tubed IC feeding capability.

On a budget the following machine seems to be the way to go. The Charmhigh CHMT48VA.

Features:

- Dimensions L 960mm*W 705mm*H 335mm

- PCB Area 10*10~355*355mm <– More than enough for the stencil print size

- XY Axis travel 400*460mm

- Z axis move range 15mm

- Pick and Place heads 2pcs

- Mounting Speed:

- With vision 3000~4000cph

- Without vision 6000cph-7000cph

- Working Precision ±0.025mm

- Reels/Feeders/Stacks/Trays:

- 8mm=22 stack

- 12mm=4 stack

- 16mm=2 stack

- 24mm=1 stack

- Front IC=14 stack

- User-defined IC tray

- Vacuum pump 2pcs in-built

- Vision system Up view and down view dual cameras

- Computer system inside Linux system inside,

- CSV file By Protel 99SE ; Altium Designer and Eagle

- Touch screen 7’’ (15.6cm*9.3cm) industry touch screen

- Support packages 0402,0603,0805,1206,1210,3528,5050, SO-16,SOT-23,SOT-89,TO-252,SOP,QFN, LQFP….different kinds of IC (max size 22*22mm)

Reflow Oven

Again, lots of people out there with reviews on ovens. The Puhui T962 series seems to be bagged a lot but there are some fixes to get it working “properly”

I am going to go with the latest iteration the T962C and see how it goes. It has had a good review from the Superhouse guy (Andrew)…

Prediction: I have a feeling I’m going to have to build an oven myself….

My Purchases

These affiliate links help me in a small way at no extra cost to you. I have personally bought from these sellers and can verify they delivered the goods.

CHMT48VA + Vibration Feeder (tube feeder)

The pick and place machine with 29 feeders and a tube vibration feeder for ICs in tubes.

3040 Stencil Printer / Manual Solder Paste Screening Machine

This stencil printer is much better than the cheaper ones as it allows you to prop the board if its thin and has variation in flatness