About 2 months ago I saw Andreas Speiss talking about using TPMS sensors for monitoring his bottle carbonation. He was having to fabricate a cap that could accomodate the sensor. It got me thinking. Why can’t I just use the outboard sensor types with a valve stem and call it day?

So I decided to add some off the shelf EXTERNAL type TPMS sensors to my brewing kegs. I call it Fermentation Temperature Pressure Monitoring System or FTPMS. Yes…I like acronyms.

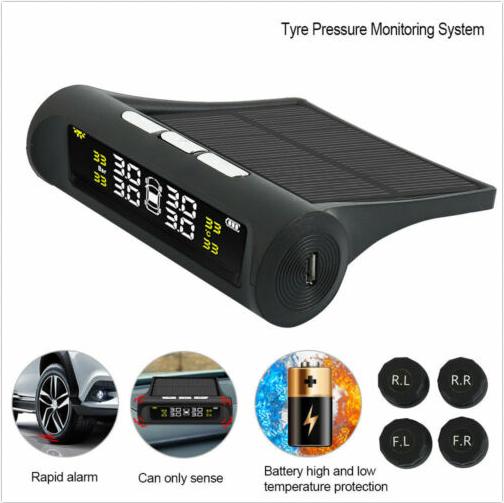

Some background if you require it….A TPMS (Tyre Pressure Monitoring System) uses wireless temperature and pressure sensors on each valve stem to monitor and warn of out of bounds conditions namely over/under-pressure, over-temperature. They report back to a central controller with a display for temperature and pressure.

These measurements are highly useful in pressure fermentation or Grünschlauchen, not so much plastic fermenter type setup…

I bought the set of four because you get the display and receiver unit which I will hack in Part 2 to allow you to run more than 4 sensors.

I used an off the shelf tyre valve stem that was designed to fit to high quality alloy wheels rather than the push in rubber type.

These are made out of stainless steel. All you have to do is drill a 8mm diameter hole in the top of the keg lid and then fit this valve assembly.

Installation

I used a 90 degree brass motorcycle valve stem for mine. Similar to the one below:

The Schrader thread was a bit shite so I had to clean it up for the TPMS sensor to fit nicely. My advice is to use the stainless steel stem shown in this post.

The Result

Thats the Rear Left sensor fitted to Fermentation Keg 1. I have two fermentation kegs so I used R.L and R.R.

On the screen it is showing the telemetry:

As you can see the screen reports back the temperatures in C and the pressures in Bar.

Parts Required

You can convert up to 4 kegs with 1 kit.

4 sensor TPMS EXTERNAL SENSORS with Receiver

In part 2, I will be finding a way to run more than 4 sensors using a custom made Arduino based 433MHz receiver….

Hi,

Really clever idea. But don’t you think we can go further and put it directly on the gas post ?

Yes I suppose you could. However I need the gas port to connect the spunding valve to for fermentation.

If you only use this for kegging then yes but you would have to make some sort of disconnect to schrader valve thread adapter.

Great idea and proof of concept. I agree with Pierrick. I’d like to see this built into a spunding valve assembly, and measure the gas volume exiting the valve. That way, with a little math, we can monitor the progress of the whole pressure fermentation, just like the PLAATO airlock.

Yes Im sure you could. I just worry about aggressive ferments that end up frothing out the entire vent line…